Our technology drives your performance.

Our shop combines top-tier equipment with expert programming to produce consistent, repeatable accuracy. Every machine is maintained to the highest standards, and all work is verified for precision.

-

Hurco VM30i

The Hurco VM30i is a high-performance CNC vertical machining center built for precision, speed, and versatility. Featuring a large work envelope, 10,000 RPM spindle, and advanced WinMax® control system, the VM30i is ideal for a wide range of applications—from prototyping to production machining. Engineered for accuracy and productivity, it’s the perfect solution for modern job shops and manufacturers.

-

Rottler VR12

The Rottler VR12 Valve Refacing Machine is a high-performance system engineered for precision valve grinding and refacing in automotive, diesel, and high-performance engines. With variable-speed control, precision collet chucking, and easy-to-use touchscreen operation, the VR12 delivers fast, accurate, and repeatable results for modern engine rebuilders and machine shops.

-

SERDI 4.5

The SERDI 4.5 is a precision valve seat and guide machine designed for high accuracy cutting in diesel, automotive, motorcycle, marine, and small engine cylinder heads. Featuring a floating centering system and air-float table, the 4.5 delivers fast setup, excellent concentricity, and repeatable results. Trusted by performance engine builders and remanufacturers worldwide

-

Rottler EM103H

The Rottler EM103H is a high-performance CNC machining center engineered for precision resurfacing, boring, and general block machining. Featuring advanced 3-axis CNC control, rigid construction, and user-friendly touchscreen interface, the EM103H is ideal for automotive, diesel, and motorsport engine builders seeking accuracy, versatility, and productivity in one machine.

-

Rottler S86A

The Rottler S86A is a state-of-the-art CNC specializing in Head resurfacing. With advanced touchscreen controls and automated operations, the S86A delivers unmatched accuracy, speed, and repeatability—ideal for engine remanufacturers, performance shops, and OEM applications.

-

SuperFlow SF-1020

SuperFlow SF‑1020 air‑flow test bench for High Performance Applications

-

DCMTech SG7000

The DCM Tech SG7000 Surface Grinder is a precision rotary surface grinding machine engineered for fast, accurate material removal on engine components such as flywheels. With a rigid design and easy-to-use controls, the SG7000 delivers flat, consistent finishes ideal for automotive, diesel, and industrial machining applications.

-

Comec VPT190

The Comec VPT190 is a professional-grade vacuum testing machine designed for quick and accurate inspection of cylinder head,cooling jackets, injector cups, valve seats and combustion chambers. With a fast-sealing system and user-friendly controls, the VPT190 ensures precise diagnostics, helping engine rebuilders detect leaks and ensure proper sealing. Ideal for machine shops and remanufacturing operations.

-

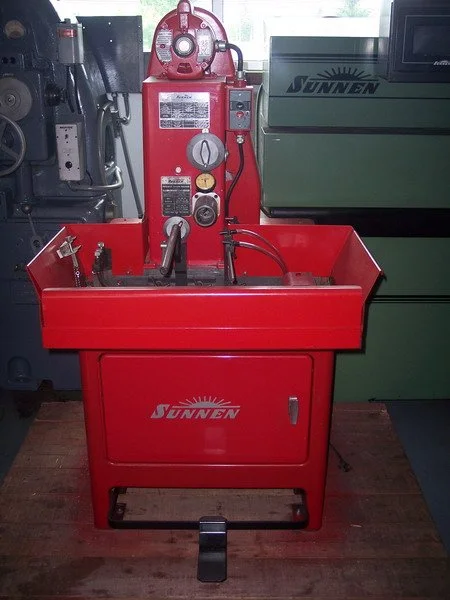

Sunnen CV-616

The Sunnen CV-616 Cylinder King is a precision vertical honing machine designed for high-accuracy cylinder bore finishing. Ideal for automotive and diesel engine rebuilding, this machine delivers superior surface finishes and consistent bore geometry. Trusted by professional engine shops for its durability, speed, and ease of use.

-

Winona Van Norman 54-43-EN Eliminator Oven

The Winona Van Norman 54-43-EN Eliminator Oven is a high-efficiency thermal cleaning system designed to remove carbon, grease, oil, and paint from engine parts and industrial components. Using controlled heat and oxygen, this environmentally friendly oven delivers consistent results with minimal maintenance. Ideal for engine remanufacturing, machine shops, and heavy-duty cleaning applications.

-

Winona Van Norman 54-43-B Rotor Blaste

Enhance your Engine head resurfacing process with the Winona Van Norman 54-43-B Rotor Blaster. Designed for high-efficiency surface preparation, this rugged machine removes rust, scale, and debris quickly and evenly. Ideal for automotive shops and remanufacturers seeking consistent, professional results.

-

Winona Van Norman 54-43-STC Shaker/Tumbler Cart

The Winona Van Norman 54-43-STC Shaker/Tumbler is a heavy-duty vibratory finishing system designed for cleaning, deburring, and polishing metal components in machine shop and automotive engine rebuilding environments. Built for continuous use, it delivers consistent surface finishing while removing oils, carbon, rust, and sharp edges from parts. Its rugged construction and reliable performance make it ideal for processing engine hardware, fasteners, and small machined components, helping shops improve part quality while reducing manual finishing time.

-

Metal Lathe PL-1340

The PL-1340 Metal Lathe is a precision-engineered toolroom lathe ideal for small-to-medium machining tasks. With a 13" swing over bed and 40" distance between centers, this lathe offers reliable turning, threading, and facing capabilities.

-

Magnaflux Magnetic Particle Inspection

Magnaflux Magnetic Particle Inspection (MPI) equipment offers industry-leading non-destructive testing solutions for detecting surface and subsurface cracks in ferrous materials. Trusted by aerospace, automotive, and industrial manufacturers, Magnaflux systems ensure fast, accurate flaw detection with reliable performance and compliance to global NDT standards. Ideal for quality control and preventative maintenance applications.

-

AXE Intimidator (SW-3660 Series) Spraywasher

The AXE Intimidator SW-3660 Series Spraywasher is a high-capacity, industrial-grade parts washer designed for fast and effective removal of grease, oil, carbon, and grime from engine components and heavy machinery. With a rugged stainless-steel build, powerful spray nozzles, and easy-to-use controls, the SW-3660 delivers consistent cleaning performance for automotive shops, diesel rebuilders, and industrial maintenance operations.

-

Sunnen LBB-1699 Rod Hone

The Sunnen LBB-1699 Rod Hone is a precision honing machine designed for accurate sizing and finishing of connecting rod bores and other small engine components. Known for its reliability and repeatability, the LBB-1699 uses Sunnen’s proven honing technology to deliver perfect roundness and surface finish. Ideal for engine rebuilders, performance shops, and industrial applications requiring tight tolerances.